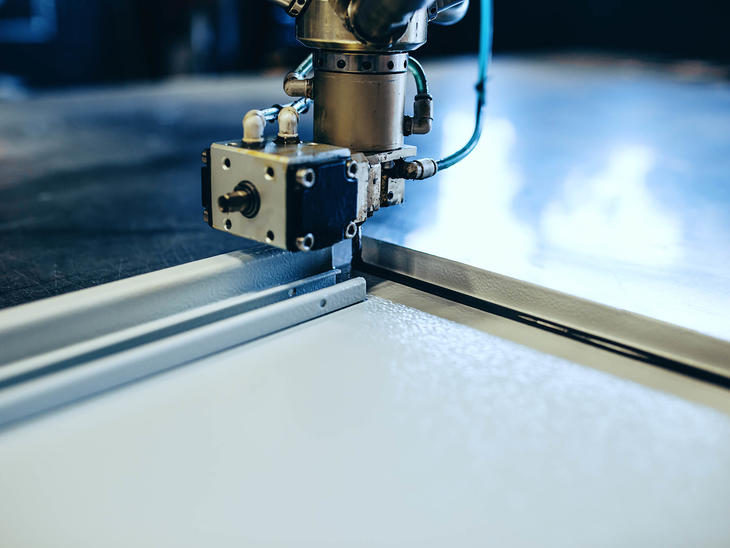

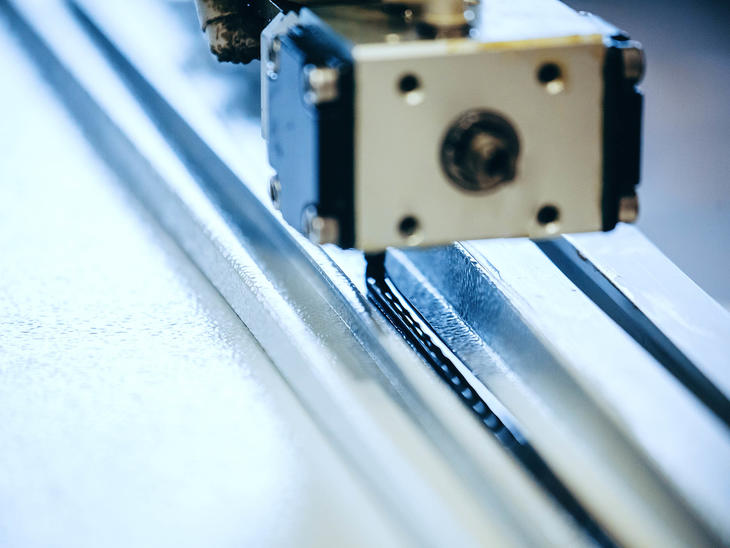

Gasket sealing

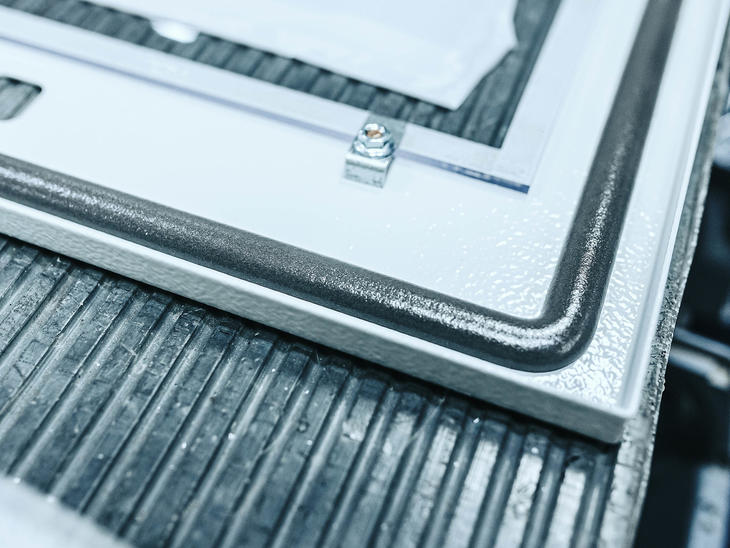

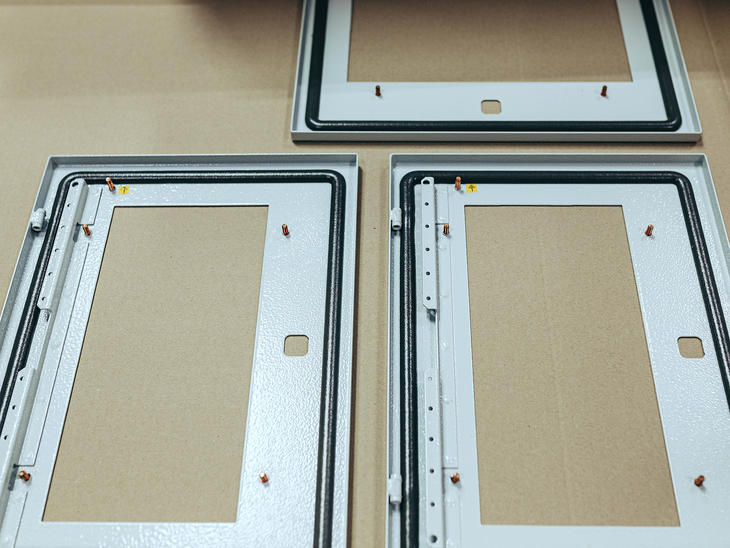

We have a special gasket sealing machine which applies a quality gasket directly to the products. The gasket we apply is a two-component polyurethane gasket which can variate from 15 to 30 mm height in a D-shape. The gasket can hold temperatures from minus 30º C to plus 70º C

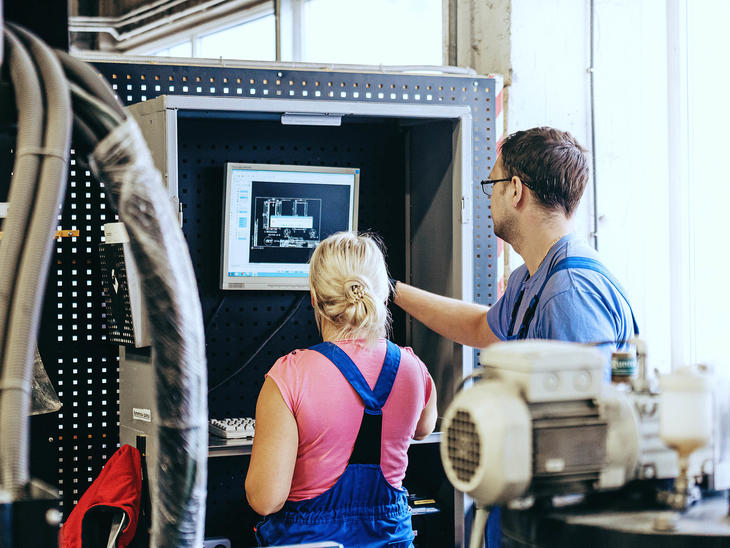

The Gasket Sealing machine eliminates the need to buy special gaskets. The gaskets are applied directly to the product in different thicknesses and forms. It is all programmed in the machine and applied automatically eliminating the risk of human errors.

Robotek HSx212 Polyurethane Dispensing System

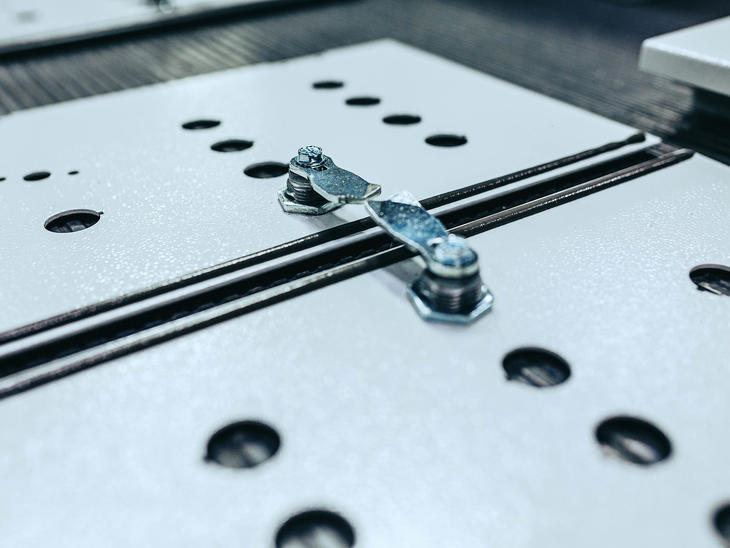

The system performs gasket placement on a flat surface of the product. Polyurethane is a two-component material by mixing polyol (component A) and isocyanate (component B). In the polyurethane dispensing system A and B components are metered, mixed and dispensed into a groove or onto a flat surface at room temperature as a ‘Formed-in-Place-Foam-Gasket’ (FIPFG) process for the production of polyurethane foam gaskets. The system control is based on an industrial CNC unit with linear, circular, and helical interpolation. The system has an operator-friendly interface with 15” TFT industrial PC of all the operating parameters. It can be quickly programmed by our professional staff for simple geometrical gasket contours such as rectangular, circular or U-formed gaskets.

Also, the system has an environmentally friendly recirculating cleaning system, in conjunction with a biodegradable cleaning agent. The cleaning agent is filtered, and waste particles are separated. The rejuvenated cleaning agent is recycled and used over and over again while no methylene chloride and no contaminated water is discharged. It is a suitable and proven alternative to conventional cleaning systems in terms of performance, economy and greatly improved environmental health and safety. The raw materials, as well as the PUR-System, are in accordance with RoHS and WEEE legislation.