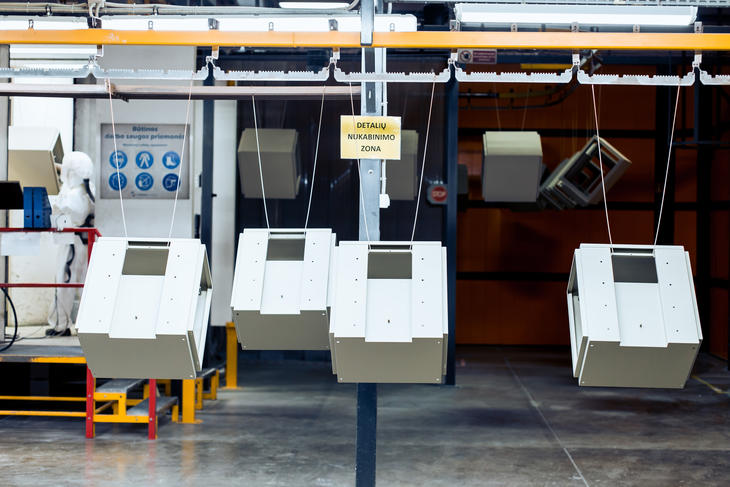

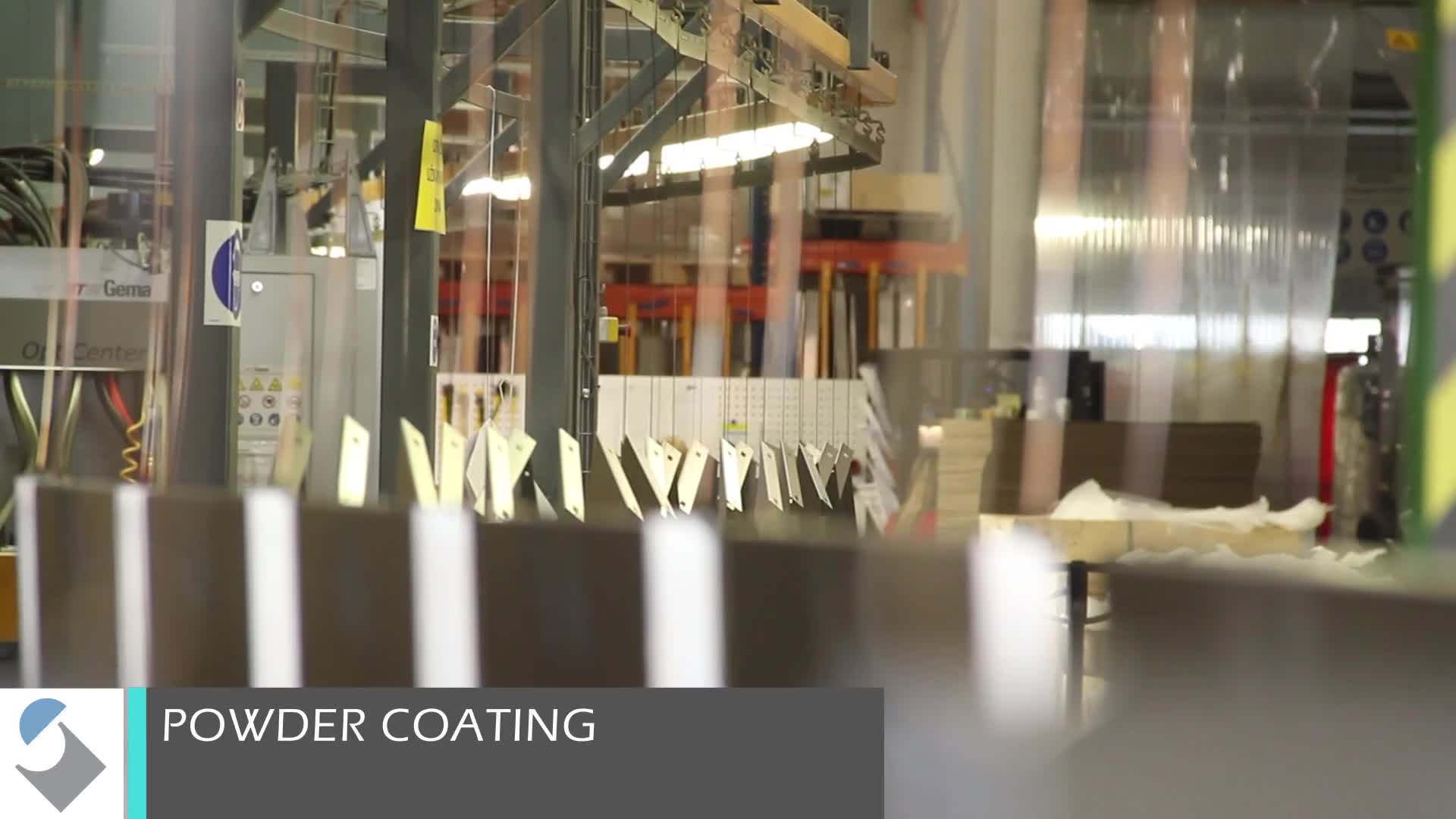

Powder coating

It is an environmentally friendly surface treatment for sheet metal products. We have a large fully automated powder coating line, including pre-treatment processes

We are proud to say over the 30 years when moving the production line from Norway to Lithuania; we have continually been improving the standards of our powder coating line. We now have the highest quality available and are a leading powder company. Our quality and process control in our powder coating line is second to none!

Powder coating is a very environmentally friendly process. It gives many advantages both with cost level and finished results. It's also possible to paint in all kinds of different colours and with different structures.

Stansefabrikken was the first company in Lithuania to install a high-capacity automated powder coating line that has an anti-corrosion function. The Oxsilan anti-corrosion pre-treatment technology is now gaining popularity fast around the world and is beginning to replace galvanization as the preferred anti-corrosion method. The new technology is the so-called dry method and has several advantages over wet coating.

Stansefabrikken's powder coating line has several coating cabinets for different colour palettes. The following max measures apply for detail coating:

Height: 1,700 mm, Width: 850 mm, Length: 2,500 mm.

.